Heat Exchangers in Dairy Industry

Plate heat exchanger in dairy industry is a crucial component of dairy processing, to guarantee that their dairy products meet industry requirements and are safe for human consumption. Despite liquid milk’s apparent stability, its processing involves intricate details. For essential tasks like pasteurization and sterilization, many dairy enterprises rely on the straightforward efficiency of plate-type heat exchangers. This versatile technology easily raises milk to the required temperature, meeting crucial safety criteria.

Diving deeper into the realm of dairy processing reveals a broader canvas. From creamy yogurts to savory cheeses, each dairy delight demands meticulous temperature control during processing and storage. Enabling these diverse products hinges on selecting the right dairy plate heat exchanger. Neglecting precise temperature control during routine processes could jeopardize essential product attributes. As the dairy processing sector evolves, businesses are wise to choose a heat exchanger tailored to the specific nature of their crafted products. Mastering the art of dairy perfection requires both expertise and a strategic approach to heat exchange technology selection.

HFM Application in Dairy Plate Heat Exchanger

Contribution of networks to the globalization of the dairy industry, all the gamers are dragged to one giant checkerboard. Although the market share is expected up to thousands of billion by 2024, it is never easy to survive in the dynamic and complex marketplace arena.

HFM has been dedicated to hygiene plate heat exchangers for more than ten years. We provide highly efficient and economical solutions and plate heat exchanger for dairy machinery for our customers.

Unveiling Pasteurization: Ensuring Quality and Safety Through Heat Treatment in the Dairy Industry

In the dynamic realm of the dairy industry, pasteurization emerges as a pivotal process, fortified by the innovation of plate heat exchangers. Crafted by Louis Pasteur in the 19th century, this technique involves heating dairy products to precise temperatures for designated periods, exterminating harmful microorganisms. Beyond its historical significance in wine and beer preservation, pasteurization’s application in the dairy industry today hinges on the efficacy of milk plate heat exchangers.

At its core, pasteurization thrives on equilibrium – eradicating microorganisms while preserving product integrity. The intricacies of temperature and duration are dictated by the dairy plate heat exchanger’s adeptness at catering to specific microorganisms. Within this spectrum, the dairy industry boasts an array of heat exchangers designed to optimize pasteurization outcomes.

Among these, Ultra High Temperature (UHT) pasteurization shines bright. Swiftly elevating temperatures beyond 135°C (275°F) for mere seconds, UHT ensures the annihilation of spores and microorganisms. This method finds its haven in dairy plate heat exchanger, protecting the essence of milk, juices, yogurt, and more. However, the art of UHT pasteurization calls for balance, as heat exposure can sway flavors and aromas.

Conversely, High Temperature Short Time (HTST) pasteurization offers a subtler approach, safeguarded by the precision of heat exchangers. Warming milk to 72°C (162°F) for a minimum of 15 seconds, HTST carves a unique niche, with a slightly shorter shelf life but an equally strong commitment to quality.

Through the intricate dance of pasteurization, dairy plate heat exchanger steps onto the stage, embodying innovation and safety. As the dairy industry continues to evolve, the synergy of these technologies ensures that milk, the lifeblood of countless products, remains wholesome, safe, and ready for consumption.

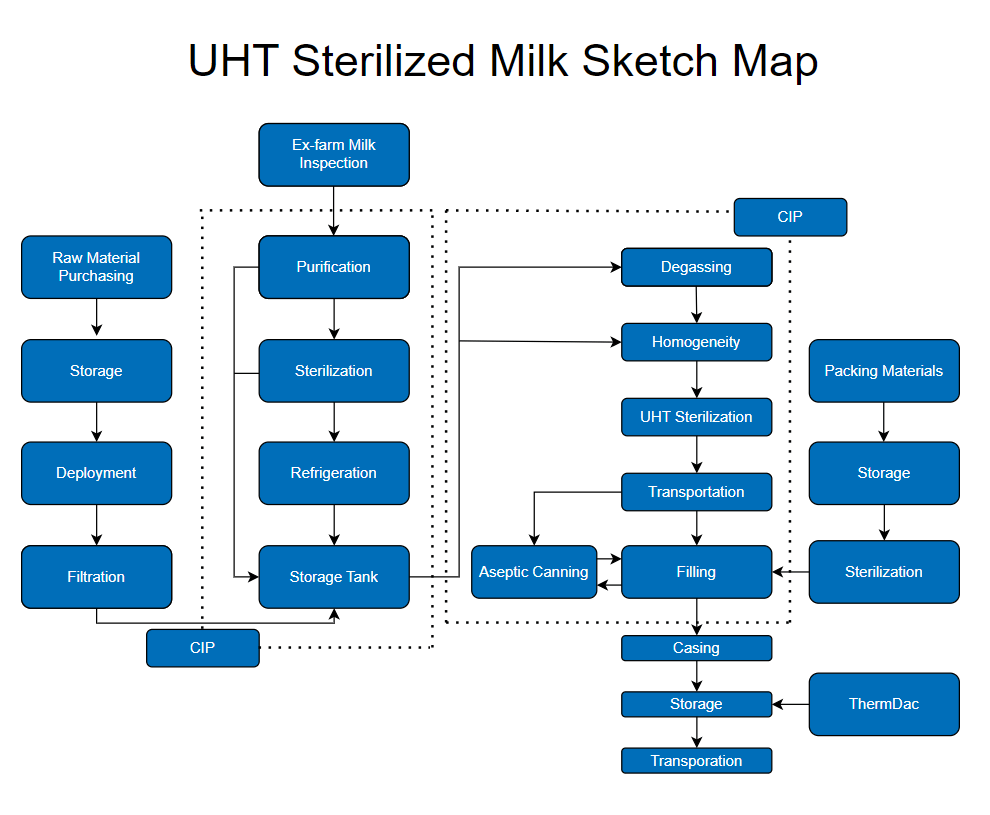

UHT Processing: Elevating Dairy Delights through Essential Stages

In the realm of dairy processing, Ultra High Temperature (UHT) stands as a complex and automated procedure, encompassing a series of stages that culminate in the creation of safe, top-notch, shelf-stable food products. This meticulously orchestrated journey involves crucial components like heating, flash cooling, homogenization, and aseptic packaging.

Heating:

A cornerstone of food processing, heating elevates product temperature to specific levels required for processing, pasteurization, or sterilization. Within the UHT context, the journey begins with pre-heating the liquid to a non-critical temperature (70-80°C for milk) before rapidly ascending to the desired temperature.

Flash Cooling:

Following the intense heat, flash cooling comes into play, rapidly restoring the product to lower temperatures. In UHT processing, flash cooling prevents overcooking, preserving the product’s essential characteristics intact.

Homogenization:

For dairy products like milk, homogenization is pivotal. This mechanical process dismantles fat globules, uniformly distributing them within the liquid. The result is a cohesive product that sidesteps the separation of cream from the liquid. Applied post-heating and pre-packaging, homogenization weaves harmony into the dairy delight.

Aseptic Packaging:

At the pinnacle of the process, aseptic packaging emerges. This technique sterilizes both the product and the packaging materials separately, ensuring a pristine environment for filling and sealing. Through this meticulous method, product quality and freshness are sustained over extended periods, void of refrigeration or additional preservation tactics. The essence of UHT processing finds its zenith in aseptic packaging, as it guards against the intrusion of bacteria and other microorganisms that jeopardize the product’s integrity.

Amidst the intricate ballet of UHT processing, these stages harmonize to deliver dairy delights that exude quality, safety, and longevity. With the aim of securing a prime position in the world of dairy processing, the UHT journey navigates multiple phases, each essential in perfecting the art of producing exceptional dairy products.

Indirect Heating System and Plate Heat Exchangers in Dairy Pasteurization

In the realm of pasteurization, two distinct approaches, direct and indirect heating, play crucial roles depending on the product and desired outcomes. While direct heating involves immediate contact with the heat source, indirect heating employs a heat transfer surface, such as a heat exchanger, to gently raise the product’s temperature.

Within indirect heating systems, a solid heat exchanger, akin to those utilized in pasteurization, is employed to heat the product. However, at elevated temperatures, higher pressures must be applied to prevent boiling. Three types of exchangers are commonly employed:

Plate Heat Exchanger

Tubular Heat Exchanger

Scraped-surface Heat Exchanger

Among these options, the plate heat exchanger stands out as the most efficient choice. Leveraging pressurized water or steam as the heating medium, these plate exchangers maximize energy conservation through integrated regeneration units that facilitate medium reuse.

HFM Plate Heat Exchangers for Dairy uphold rigorous quality and safety standards, aligning with GRG, FDA, and SGS certifications, ensuring top-tier products that prioritize quality and safety. With specialized focus on milk plate heat exchanger and dairy plate heat exchanger, our solutions are tailored to meet the unique demands of the dairy industry. Whether you’re seeking heat exchangers for the dairy industry or those used in the dairy industry, HFM delivers excellence in heat transfer technology for your dairy processing needs.

Unsure about which Plate Heat Exchanger to utilize?

Contact us for 1-on-1 Expert guidance and custom design services tailored specifically to your needs!

Plate Heat Exchanger for Milk Pasteurization Process Flow

Technical Requirements for Production Process

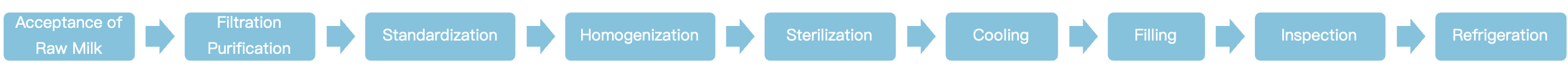

In the realm of dairy production, adherence to rigorous technical requirements is paramount to ensure the production of high-quality sterilized milk. This comprehensive process involves several key stages, each contributing to the excellence of the final product. Let’s explore these stages in detail, highlighting their significance in the context of milk plate heat exchangers and their role in the broader heat exchangers used in the dairy industry.

1. Acceptance of Raw Milk and Classification:

The foundation of sterilized milk quality rests upon the quality of raw milk. Rigorous management and meticulous testing of raw milk are indispensable to uphold its standards. Only raw milk meeting specified criteria earns its place in producing sterilized milk.

2. Filtration or Purification:

Milk filtration and purification take center stage to eliminate dust and impurities, ensuring pristine milk quality. These processes align harmoniously with the efficiency of dairy plate heat exchangers, working collectively to purify the milk.

3. Standardization:

Achieving milk’s desired fat content is essential for standardized quality. Across different nations, standards vary, with low-fat milk containing around 0.5% fat, and typical milk containing 3%. Notably, China mandates 3.0% fat content for sterilized milk, necessitating meticulous standardization.

4. Homogenization:

This step, executed at a consistent temperature of 65°C and pressure of 10 to 20 MPa, refines milk’s consistency. The synchronized role of plate heat exchangers in dairy processes contributes to the successful homogenization, optimizing milk attributes.

5. Sterilization:

Heat sterilization emerges as a pivotal method to combat potential microbial risks in pasteurized fresh milk. The harmonious interplay of heat exchangers in dairy processes ensures effective sterilization, bolstering milk’s stability during storage, combating rancidity, and arresting microorganism growth.

6. Cooling:

Inhibiting bacterial proliferation and extending milk’s shelf life, cooling is pivotal. Whether cooling milk to approximately 4°C or efficiently handling ultra-high temperature milk, heat exchangers’ contribution is central to maintaining optimal temperatures.

7. Filling:

Filling marks the final stage, poised to preserve milk’s integrity. From glass bottles to plastic containers, each filling vessel serves as a guardian of milk’s essence. Heat exchangers play an integral role in sustaining the temperature integrity of filled containers.

Amidst this intricate symphony of processes, the significance of milk plate heat exchangers in dairy production stands pronounced. These heat exchangers align harmoniously with broader heat exchangers in the dairy industry, culminating in the production of premium sterilized milk.

Plate Heat Exchanger for Dairy Case Study – HTST Pasteurization

When considering dairy processing, the plate heat exchanger assumes a pivotal role in achieving optimal results. This case study delves into the application of HTST pasteurization utilizing a plate heat exchanger in a stepwise manner.

1. Heat Recovery Section:

In the first phase, the pre-cooled 5°C fresh milk engages with the plate heat exchanger in the heat recovery section, absorbing heat to reach approximately 65°C. This initial step sets the foundation for subsequent stages.

2. Sterilization Section:

The plate heat exchanger ensures precise heat treatment during the sterilization phase. This strategic utilization of heat ensures the elimination of potential contaminants while maintaining the integrity of the milk.

3. Cooling Section:

The final step involves the plate heat exchanger, where ice water serves as the cooling medium. The milk, having undergone pasteurization, is effectively cooled to preserve its quality.

Throughout the process, the plate heat exchanger in dairy industry not only facilitates the efficient exchange of thermal energy but also underscores the importance of precision in dairy processing. The integration of advanced heat exchangers in dairy industry safeguards the product’s safety and quality.

In conclusion, the utilization of a plate heat exchanger in the HTST pasteurization of dairy products exemplifies the pivotal role of cutting-edge heat exchangers used in dairy industry. This case study underscores how innovative thermal solutions, such as the plate heat exchanger, contribute to the overall enhancement of dairy processing efficiency and product integrity.

Plate Heat Exchanger for Dairy Design Solution

Plate material: 304 or 316

Gasket: NBR

1. Heat recovery section: Both sides of the medium are milk

Hot side inlet temperature: 85 degrees or more

Cold side inlet temperature: 5 degrees outlet temperature 65 degrees

2. Sterilization section:

Cold side: preheated milk; temperature: inlet: 65 out 85 or more

Hot side: hot water 95 or more

3. Cooling section:

Cold side: milk that needs to be preheated and ice water

Hot side: hot milk that kills bacteria

Application of Plate Heat Exchanger for Dairy – Ice Cream Production

The plate heat exchanger, which incorporates representatives for ice cream, is extensively utilized in the food industry. The ice cream production process comprises various steps such as sterilization, cooling, mixing, filling, and packaging of the mixture.

Prior to homogenization, the temperature of the ice cream mixture must be meticulously controlled to range between 65℃ to 70℃ using the plate heat exchanger. Deviations from this range can lead to the condensation of fat or a foul odor. Subsequently, the plate heat exchanger is utilized for sterilization prior to transferring the material to the ageing tank, which brings the material to the required temperature for aging.

This process optimizes cost efficiency by combining heating and sterilization procedures. Due to the relatively viscous nature of ice cream material, Hofmann’s BNF series of plate heat exchangers with wide flow paths and high heat transfer efficiency presents an excellent choice for this heat transfer operation.

Contact Us today for professional and tailor-made solutions that fit your requirement!