HFM Waste Water Heat Exchangers

Amidst the growing concerns about wastewater management, a global shift towards stricter regulations for water disposal has placed environmental safety and public health at the forefront. In urban centers, municipal sewage treatment facilities play a pivotal role, efficiently managing substantial water volumes and addressing energy demands on a daily basis.

At HFM, our commitment extends to enhancing heat exchanger efficiency, offering solutions that address the intricacies of wastewater treatment. Explore how our advanced technologies contribute to sustainable solutions for a cleaner environment.

Heat exchangers for waste water treatment are pivotal components in efficient waste water recovery systems. These devices harness the latent heat within urban sewage, allowing for effective heat exchange. During summer, excess heat from buildings is channeled into city sewage via specialized units, and in colder months, the heat latent within city sewage is extracted and used for heating. Urban sewage heat potential depends on wastewater temperature dynamics influenced by treatment and seasonal variations.

The Role of Heat Exchangers in Wastewater Treatment

In the realm of wastewater treatment, heat exchangers are pivotal components that enhance efficiency, promote energy conservation, and support environmental sustainability. This section explores how heat exchangers contribute to key aspects of wastewater treatment processes.

1. Heat Recovery for Wastewater Treatment

Heat exchangers play a crucial role in heat recovery from wastewater streams. These devices efficiently transfer thermal energy between different wastewater flows, contributing to the reduction of energy consumption and the optimization of heat resources.

2. Energy Efficiency and Wastewater Heat Recovery

Efficient heat exchange within wastewater treatment systems results in reduced energy consumption. Heat exchangers ensure the effective utilization of thermal energy, which not only lowers operational costs but also aligns with sustainable wastewater treatment practices.

3. Environmental Sustainability in Wastewater Heat Recovery

Effective heat exchange in wastewater treatment contributes to enhanced environmental sustainability. It aids in maintaining ideal temperatures during treatment stages, facilitating contaminant removal and high-quality effluent production. This aligns with broader environmental protection goals.

4. Corrosion-Resistant Heat Exchanger Materials

The selection of appropriate heat exchanger materials is crucial to withstand the corrosive conditions often encountered in wastewater treatment. Stainless steel and specialized coatings are commonly employed, ensuring long-term durability and performance, even in harsh wastewater environments.

5. Tailored Solutions for Specific Wastewater Needs

Heat exchangers offer adaptability to meet specific project requirements in wastewater treatment. They can be customized to accommodate variations in flow rates, temperatures, and treatment objectives. This versatility ensures seamless integration into diverse treatment processes.

In summary, heat exchangers are indispensable in wastewater treatment, contributing to improved energy efficiency, environmental sustainability, and the overall efficacy of treatment systems. In the following sections, we will delve deeper into the specific applications and benefits of heat exchangers in various wastewater treatment processes.

Types of Heat Exchangers Used in Waste water Treatment

Heat exchangers play a pivotal role in wastewater treatment, optimizing heat transfer processes and promoting energy efficiency. Different types of heat exchangers are strategically employed to meet the unique demands of wastewater treatment systems. Let’s explore these key categories, briefly mentioning their advantages, and then we will delve deeper into the advantages of Plate Heat Exchangers (PHEs) in the next section.

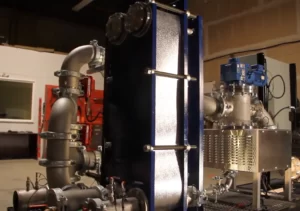

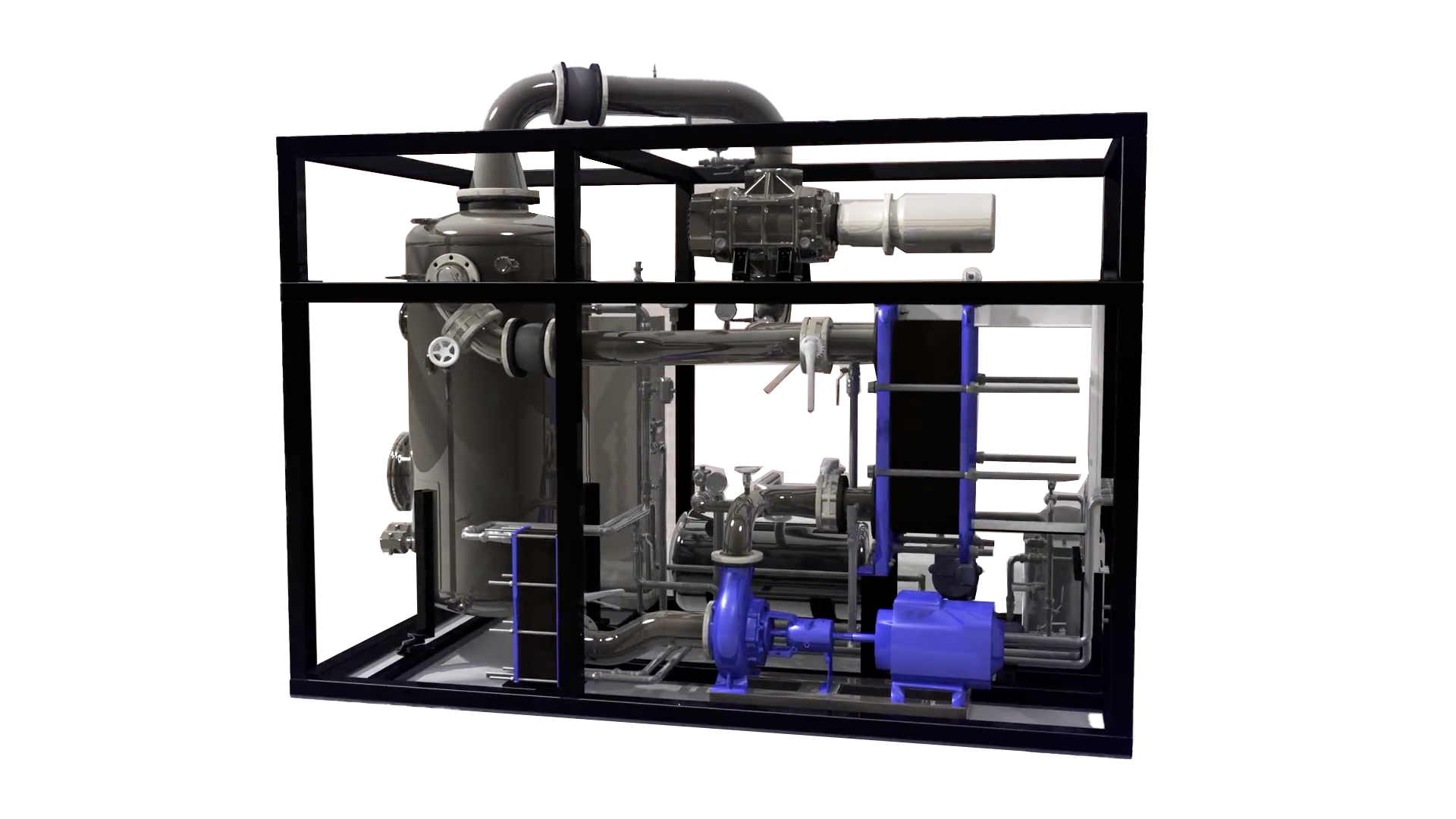

A. Plate Heat Exchangers (PHEs) for Wastewater Treatment

Plate Heat Exchangers (PHEs) are among the most versatile choices in wastewater treatment due to their compact design and exceptional heat transfer efficiency. They are applied in various processes, including heat recovery, pasteurization, and heating/cooling low-viscosity fluids.

Advantages: PHEs excel in efficient heat transfer, saving space, and simplifying maintenance. They are ideal for handling wastewater with fluctuating temperatures and flow rates.

B. Shell and Tube Heat Exchangers in Wastewater Treatment

Shell and tube heat exchangers find extensive use in large-scale wastewater treatment plants. They effectively manage high flow rates and are crucial in processes requiring precise temperature control, such as sludge digestion and anaerobic treatment.

C. Tube-in-Tube Heat Exchangers for Wastewater Applications

Tube-in-tube heat exchangers are versatile and well-suited for smaller-scale wastewater treatment systems. They frequently serve in water-to-water heat exchange applications.

D. Plate-Fin Heat Exchangers for Wastewater Treatment

Plate-fin heat exchangers are chosen for their compactness and efficiency, making them ideal for heat recovery systems and industrial wastewater treatment.

E. Spiral Heat Exchangers in Wastewater Treatment

Spiral heat exchangers are valued for their resistance to fouling and ability to handle viscous fluids, making them suitable for demanding wastewater treatment processes.

Advantages of Plate Heat Exchangers in Wastewater Treatment

Among all the heat exchangers, Plate Heat Exchangers (PHEs) have become instrumental in wastewater treatment for several compelling reasons. Their unique design and efficiency make them a preferred choice in various wastewater treatment processes. Here are the key advantages of using Plate Heat Exchangers in wastewater treatment:

1. Exceptional Heat Transfer Efficiency: Plate Heat Exchangers are renowned for their high heat transfer rates. Their corrugated plates create turbulence in the fluid flow, maximizing heat exchange between two streams. This results in efficient heating or cooling of wastewater, which is crucial in various treatment phases.

2. Compact and Space-Efficient: PHEs are significantly more compact than traditional shell-and-tube heat exchangers. This space-saving design is especially valuable in crowded wastewater treatment plants where real estate is at a premium. Their compact size allows for easy installation and integration into existing systems.

3. Versatility in Handling Varying Temperatures: Wastewater temperatures can fluctuate significantly throughout the year. Plate Heat Exchangers are versatile in handling these variations. They can efficiently transfer heat from one stream to another, regardless of whether the wastewater is at a high or low temperature.

4. Corrosion Resistance: Wastewater often contains corrosive substances that can damage conventional heat exchangers. PHEs are constructed with corrosion-resistant materials, such as stainless steel, ensuring their longevity even in harsh wastewater environments.

5. Minimal Fouling and Scaling: Fouling and scaling can reduce the efficiency of heat exchangers over time. Plate Heat Exchangers are designed to minimize fouling due to their smooth plate surfaces. This reduces maintenance requirements and ensures consistent performance.

6. Energy Efficiency: PHEs are known for their energy efficiency. They recover and reuse heat from wastewater, reducing energy consumption and operating costs. This eco-friendly approach aligns with sustainable wastewater treatment practices.

7. Scalability: Whether your wastewater treatment plant handles a small volume or a large-scale operation, Plate Heat Exchangers can be scaled to meet your specific needs. This scalability makes them suitable for various applications within wastewater treatment.

Maintenance and Considerations for Plate Heat Exchangers in Wastewater Treatment

Proper maintenance is crucial to ensure the longevity and optimal performance of plate heat exchangers (PHEs) used in wastewater treatment. These intricate devices efficiently transfer heat between two fluid streams, but they require regular attention and care to continue operating at peak efficiency. Here, we delve into the key maintenance practices and important considerations for PHEs in the context of wastewater treatment.

1. Routine Cleaning and Inspection

Regular cleaning is essential to prevent fouling and scaling, common issues in wastewater applications. Sediments, debris, and organic matter can accumulate on the heat exchange surfaces over time, reducing heat transfer efficiency. Routine inspections should include checks for fouling, corrosion, and leaks.

2. Scaling and Fouling Mitigation

Scaling, caused by mineral deposits, and fouling, resulting from organic or biological substances, can significantly degrade PHE performance. Employ effective anti-scaling and anti-fouling measures such as chemical treatments or mechanical cleaning devices. Choose materials that resist corrosion and fouling, ensuring a longer lifespan for your PHE.

3. Temperature and Pressure Control

Maintain strict control over temperature and pressure within the PHE. Excessive temperature variations or pressures can lead to mechanical stress and reduce the PHE’s operational life. Implement control systems that monitor and adjust these parameters as needed.

4. Gasket Replacement

Gaskets play a critical role in sealing the plates and preventing fluid cross-contamination. Over time, gaskets can wear out or degrade due to exposure to harsh wastewater conditions. Regularly inspect and replace gaskets when signs of wear or leakage occur.

5. Corrosion Protection

Wastewater often contains corrosive elements that can damage PHE components. Select PHE materials and coatings that are resistant to corrosion. Stainless steel is a common choice due to its corrosion-resistant properties. Implement a comprehensive corrosion protection plan to extend the PHE’s lifespan.

6. Regular Performance Testing

Conduct periodic performance tests to assess heat transfer efficiency. These tests help identify any decline in performance, allowing for timely maintenance and adjustments. Monitoring efficiency ensures that the PHE continues to operate effectively.

Application of Plate Heat Exchanger in Waste Water Treatment Plant

Sewage side: 80° C – 33° C

Circulating water volume: 150 t / h

Clear water side: 75° C – 28 ° C

Circulating water volume: 150 t / h

Plate material: Stainless Steel 316

Gasket material: EPDM

The separation of clean water and wastewater within a heat exchanger is fundamental to its operation. Channels or plates within the exchanger keep these liquids physically apart while facilitating heat transfer, preventing cross-contamination, and preserving water quality. This separation is essential for the safe and efficient treatment of wastewater.

Leveraging Plate Heat Exchangers for Sustainable Wastewater Treatment

In conclusion, plate heat exchangers (PHEs) have emerged as indispensable assets in the realm of wastewater treatment. Their exceptional heat transfer efficiency, durability, and adaptability make them ideal for various stages of the wastewater treatment process. Whether it’s heat recovery, condensation, or pressure-swing adsorption, PHEs excel in optimizing these critical operations.

The advantages of PHEs extend beyond their technical prowess. Their sustainable design not only conserves energy but also minimizes environmental impact. By harnessing the latent heat within wastewater, PHEs contribute to more efficient and eco-friendly wastewater treatment processes.

In many parts of the world, wastewater treatment plants (WWTPs) are being challenged to become net zero in terms of carbon by 2030. Achieving such challenging targets will require the recovery of the energy contained in the incoming wastewater streams and using this energy to provide the heat and power necessary for wastewater treatment and solids handling.

At HFM, we understand the vital role Plate Heat Exchangers play in wastewater treatment. We are committed to providing cutting-edge solutions that cater to the specific needs of your wastewater treatment system. Our waste water heat exchangers are designed to withstand the challenges of wastewater environments, from fouling and scaling to corrosion. Moreover, we offer a one-year free product warranty and unparalleled after-sales service to ensure your PHEs continue to perform at their best.

Ready to optimize your wastewater treatment system with HFM Plate Heat Exchanger? Contact us today to learn more about our high-quality, cost-effective solutions and revolutionize your wastewater treatment with the efficiency and reliability of HFM’s PHE technology.