Plate Heat Exchnager for HVAC Industry

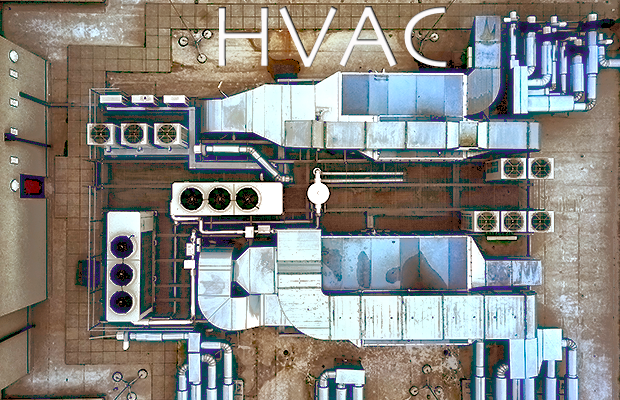

In the field of HVAC (Heating, Ventilation, and Air Conditioning), the HVAC heat exchanger plays a pivotal role as a fundamental component responsible for thermal energy exchange. Its primary function involves facilitating the transfer of heat between fluid mediums, ensuring precise temperature control in diverse applications such as residential heating systems, industrial processes, and air conditioning units.

Heat exchangers HVAC systems contribute significantly to energy efficiency by recovering and redistributing thermal energy. They are designed to optimize the heating and cooling processes, thereby enhancing overall system performance. As an essential element in the HVAC industry, heat exchangers enable the effective regulation of ambient conditions, providing comfort and functionality in various environments.

The efficiency and reliability of HVAC systems rely on the seamless operation of plate heat exchanger for HVAC. These devices are engineered to meet specific requirements, considering factors such as heat load, fluid properties, and environmental conditions. Whether in residential, commercial, or industrial settings, the strategic integration of heat exchangers ensures optimal thermal management and overall effectiveness of HVAC systems.

In HVAC system, efficient thermal energy exchange is vital. HVAC systems depend on Heat Exchangers, and Plate Heat Exchangers (PHE) are a valuable solution. HFM expertise in providing high-quality PHE, seamlessly integrates into HVAC. Our Plate Heat Exchangers contribute to energy efficiency, space saving, and customizable solutions. Contact us or send us an email at [email protected] to enhance your HVAC applications.

Understanding HVAC Heat Exchangers

Heat Exchangers are essential components in HVAC systems, facilitating the exchange of thermal energy between different fluid streams. In heating applications, they transfer heat from a warm fluid to a colder one, ensuring efficient space heating. Conversely, in cooling applications, they remove heat from the air, providing effective cooling solutions.

The importance of Heat Exchangers lies in their ability to optimize energy usage, improve system efficiency, and contribute to environmental sustainability. By recovering and redistributing thermal energy, these devices enhance the overall performance of HVAC systems.

Types of Heat Exchanger in HVAC

Various types of Heat Exchangers are employed in HVAC systems, each designed to fulfill specific requirements. One prominent type is the Plate Heat Exchanger (PHE), known for its efficiency, compact design, and versatility.

Plate Heat Exchangers (PHE): These exchangers consist of a series of thin plates with corrugated patterns, allowing for efficient heat transfer between fluids. PHEs are favored in HVAC applications for their compact size, high heat transfer rates, and ease of maintenance.

While PHEs are a key focus due to their prevalence and advantages, other types of heat exchangers, such as shell and tube exchangers or finned coil exchangers, are also used based on specific HVAC system requirements.

Advantages of Plate Heat Exchangers

Plate Heat Exchangers (PHE) stand out as a reliable choice in HVAC systems, known for their efficiency in optimizing both heating and cooling processes. This efficiency is a key factor contributing to their widespread adoption in various applications. Notably, the space-saving design of PHE makes them highly practical for diverse installations, offering flexibility in system setups. The customizable nature of these heat exchangers allows for tailored solutions, ensuring precise temperature control and efficient thermal management in HVAC systems. This adaptability is particularly valuable in addressing the specific needs of different environments and applications, making Plate Heat Exchangers a reliable choice in HVAC technology.

Maintenance and Cleaning of Plate Heat Exchanger

In HVAC systems, maintaining and cleaning Plate Heat Exchangers (PHE) is paramount for ensuring prolonged efficiency and optimal performance. Regular maintenance is key to preventing issues and ensuring the seamless operation of PHE in various HVAC applications. Guidelines for maintaining PHE involve thorough inspections, cleaning of plates and gaskets, and addressing any potential leaks or damages. This routine upkeep not only enhances the lifespan of the equipment but also contributes to energy efficiency. The importance of adhering to a maintenance schedule cannot be overstated, as it directly influences the overall functionality and reliability of Plate Heat Exchangers in HVAC systems.

Overcoming Challenges in Heat Exchanger HVAC

Addressing challenges in HVAC Heat Exchanger systems is a crucial aspect of ensuring consistent performance. Common issues, such as fouling, corrosion, and scaling, can impact the efficiency of Plate Heat Exchangers (PHE). To overcome these challenges, strategic solutions are employed, including implementing effective cleaning protocols, selecting corrosion-resistant materials, and utilizing proper water treatment methods. Additionally, maintaining accurate records of operating conditions and regularly monitoring performance indicators helps in early detection and prompt resolution of potential problems. By proactively tackling challenges, HVAC systems equipped with Plate Heat Exchangers can maintain optimal functionality, contributing to energy efficiency and reliable operation across various applications.

Ready to optimize your HVAC system? Our PHE solutions cater to diverse HVAC applications, ensuring reliable thermal management. Discover the benefits of customization, space-saving design, and efficiency in heating and cooling processes. Take the next step towards an optimized HVAC system.

Choosing the Right Plate Heat Exchanger for HVAC System

When selecting a Plate Heat Exchanger (PHE) for HVAC applications, it is crucial to consider various factors to ensure optimal performance. The efficiency of your HVAC system depends on the strategic choice of a PHE that aligns with your specific needs. Factors such as heat load, fluid properties, and environmental conditions play a significant role in this decision-making process. Our PHEs offer customization options, allowing you to tailor solutions for precise temperature control and efficient thermal management. Explore our range to find the perfect Plate Heat Exchanger that meets your requirements and enhances the overall effectiveness of your HVAC system.

Conclusion

In conclusion, this guide has provided insights into HVAC and Plate Heat Exchangers (PHE), emphasizing their significance in various applications. Throughout the sections on maintenance, challenges, and industry trends, we’ve highlighted the practical aspects of integrating PHEs into HVAC systems. If you have specific inquiries or require personalized assistance, HFM is here to help. Explore our range of products, and let us tailor a Plate Heat Exchanger solution to meet your HVAC needs effectively. Ready to optimize your HVAC system? Fill out the enquiry form below, and our team will be in touch promptly.